Manufacturing Reimagined: Real-Time Security & Efficiency

Manufacturing Solutions

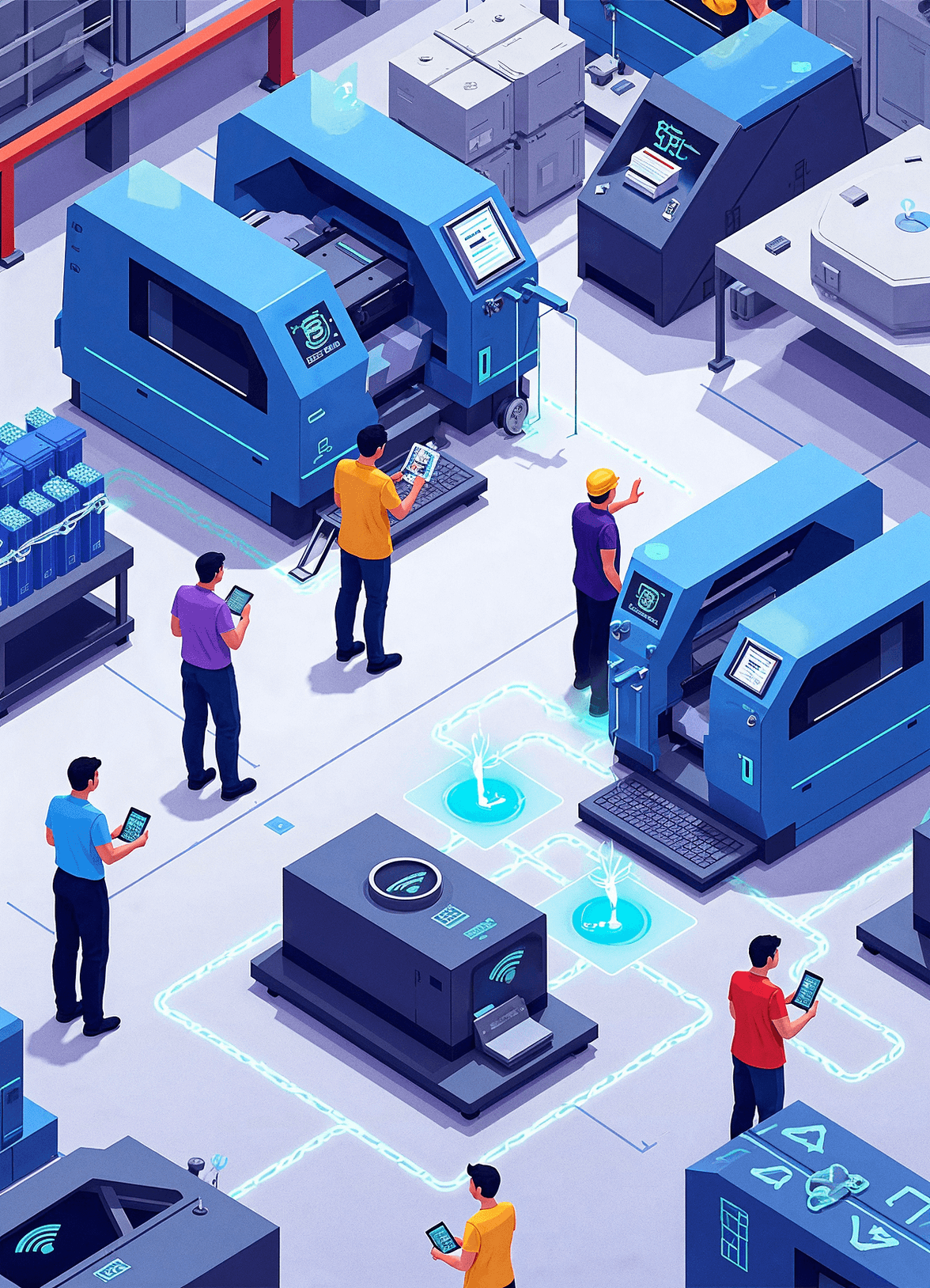

A Smarter Production Floor

Real-time visibility and tracking empower manufacturing facilities to stay safe, compliant, and ahead of the curve. Whether it's mission-critical equipment, vehicles, or personnel, Fluid Mobility lets you track, monitor, and control a multitude of factors. By digitally integrating your manufacturing environment, you'll uncover new efficiencies while optimizing safety, security, and local compliance – all without breaking a sweat.

Creating a digital map of your industrial environment unlocks new efficiencies and supercharges existing ones. From streamlined workflows to personnel and asset tracking, Fluid provides an end-to-end solution fueled by the countless data points across your organization.

- Asset tracking: Say goodbye to hide-and-seek with your assets! Eliminate manual searching, freeing up your team for tasks that generate a higher ROI.

- Automated decision-making: Real-time location data empowers you to make smarter decisions, faster.

- Bottleneck busting: Identify and eliminate production bottlenecks by tracking the location and movement of materials and equipment.

- Data-driven insights: Data analytics processes historical data to uncover hidden inefficiencies and recommend improved practices, streamlining operations.

- Indoor navigation: Guide your personnel with dynamic pathing to any place or asset across your entire area of operations.

- Seamless integration: Connect siloed processes with improved communication capabilities and data sharing.

- Enhanced workflows: Implement mandated rules based on movement and location data, enabling faster issue resolution and minimizing downtime.

- Streamlined processes: Trigger actions based on the movement of tracked assets and personnel.

The Result: With real-time monitoring and data analytics, Fluid will ensure your organization unlocks its full potential. By empowering your workforce with more dedicated production time, you'll achieve new levels of efficiency and ROI. Think of it as giving your production floor a shot of espresso – only it lasts longer and doesn't involve the jitters.

Industrial environments can be hazardous places. Monitoring the movement and positioning of your equipment and people drives safety and security outcomes. Manage access across your production floor with tailored permissions for a more secure environment. Integrate movement- and location-based data analytics with a real-time view of your production floor to empower your organization with real-time data feeds.

- Real-time alerts: Receive instant alerts, visibility, and pathing in critical safety/security scenarios.\

- Lone/stranded worker monitoring: Respond to emergency scenarios instantly with lone/stranded worker monitoring and tracking.

- Geofencing: Create Geofences with custom rules, including access permissions, app permissions, and more. Be alerted instantly if/when a person or asset enters or leaves a hazardous or restricted area and trigger alerts and responses.

- Collision avoidance: Monitor vehicle behavior to prevent collisions by identifying if they are driving too close to each other in speed pitlanes or on a collision course with other vehicles or workers.

- Tailored mobile device permissions: Tailor mobile device permissions by location and receive alerts if permissions are violated.

- Muster and pathing capabilities: Ensure your staff are located and evacuated in case of emergency. Real-time visibility ensures missing staff are located promptly.

The Result: Real-time visibility, monitoring, and tracking are essential to securing the modern industrial environment. With a 24/7, bird’s-eye view of your operations, organizations not only address safety and security incidents, but reduce their occurrences. It's like having a security guard who never blinks, takes breaks, or needs a coffee refill.

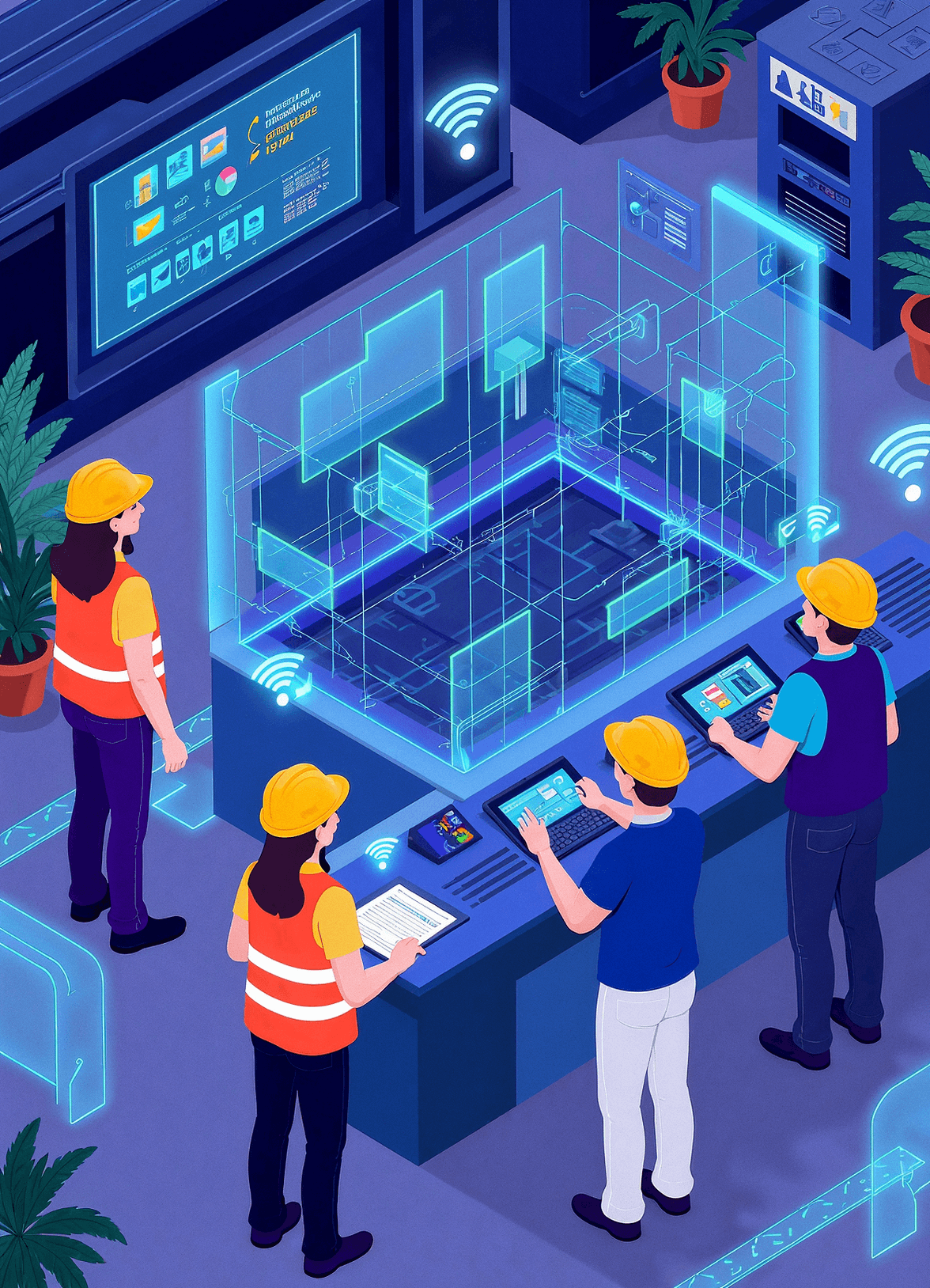

Manufacturing floors face growing Health and Safety requirements. Amidst a constantly evolving production floor – and its attendant safety and security protocols – organizations face many challenges. Fluid ensures your organization stays within local compliance requirements.

- Real-time tracking: Continuously monitor your entire area of operations to ensure assets and personnel are working within compliance regulations, such as forklift speeds.

- Environmental monitoring: Ensure assets are stored at the correct temperature and humidity.

- Vehicle movement monitoring: Monitor vehicle movement, such as forklifts, to ensure they do not exceed local speed limits.

Ready to streamline your manufacturing operations and boost your bottom line?

Let's chat! We promise, no high-pressure sales tactics – just real solutions tailored to your needs.